CNC タンデム プレス ブレーキ: 精度と効率で金属 形成 を 革命 的 に する

2025年9月24日 製造技術ニュース

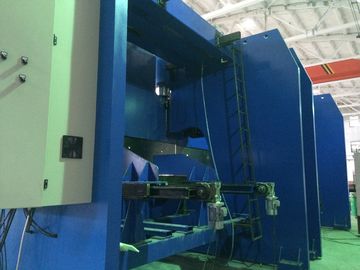

制度の導入CNCタンデムプレスブレーキ鉄板を曲げるときに 卓越した精度と効率を 提供しています 高性能アプリケーション用に設計されていますこの高度な機械はCNC制御システムこの業界ではこれまで見たことのない精度と多用性を 提供します

CNCタンデムプレスブレーキとは?

A についてCNCタンデムプレスブレーキ特殊な金属形状の機械で,大きな鋼板を様々な形状と形状に折りたたむために使用されます.Delem DAシリーズ CNC制御システム含めDA-52,DA-56,DA-65WそしてDA-66Tこのプレスブレーキは,屈曲プロセスに優れた制御を提供し,製造者は,大きくて複雑な作業部件でも完璧な結果を達成することができます.

高級機能が備わっています二国間偏差補償,電動水力サーボ制御装置そしてシンクロニゼーション技術, CNC タンデムプレスブレーキは,高速,正確,効率的な操作を保証し,厳格な基準を要求する産業にとって理想的な選択です.

主要 な 特徴 と 技術

-

電動水力サーボシステム

機械は最先端の技術で装備されています電動水力サーボシステムこのシステムはスライダの動きを非常に正確に制御します最小の誤差で一貫した屈曲結果を保証する.

-

双面偏差補償

機械は,特許技術を用いて,プレスブレーキの両側での傾きを補正します.これは,大きな鋼板でさえ,正確に曲がることを保証します.材料の浪費が少なくて優れた結果が得られる.

-

カスタマイズ可能なCNC制御システム

顧客は様々な製品から選択できますデレム 制御システム,例えば,DA-52,DA-56,DA-65WそしてDA-66T. 各システムには,自動屈曲力調整,多軸制御そしてUSBインターフェースプログラムと操作を簡単にするため2Dグラフィックインターフェース操作者が曲げ過程を視覚化できるようになり,より精密でプログラミングエラーが少なくなります.

-

高い 精度 と 効率

機械は同期原理プレスブレーキユニットが完全に調和して動作することを保証します.ボッシュのプロポーションバルブ同期精度を向上させ,機械の運用効率をさらに向上させる.

-

柔軟 な 操作

重要なことは折りたたみの鋼板創り出すことメタルパネル形づくりを重金属の加工部品機械は,様々なアプリケーションに対応するために必要な汎用性を提供します.開いた高度調整,a作業台補償装置そしてエクセンティックな仕事折りたたみ作業の幅を広げるのに適しています

産業間での応用

についてCNCタンデムプレスブレーキ工業における高精度屈曲に最適です.

-

鉄鋼構造物: 鉄鋼部品の製造に最適鉄塔,トラック車そして重荷用インフラ.

-

金属製造: オーダーメイド生産に最適金属プレートそして装飾工業用部品.

-

建設: 構造部品の製造に広く使用されています建築の枠組み他の大規模な建設プロジェクト.

-

エレクトロニクスと電気キャビネット: 折りたたみ部品に必須電気キャビネットそして電気用収納器.

高質 の デザイン と 耐久 性

についてCNCタンデムプレスブレーキ耐久性のために作られています高強度フレーム機械のシリンダの表面は耐磨性熱処理寿命を延長し,長期的に機械の性能を向上させる.

尺寸と仕様:

競争優位性 と 販売後 サポート

卓越した技術に加えて,CNCタンデムプレスブレーキは格安な価格そして高性能顧客は以下からも恩恵を受けます.

-

1 年間の保証心の安らぎのために

-

迅速で高品質のアフターサービスダウンタイムを最小限に保つ.

-

パーソナライズされた機械設計個々の顧客のユニークなニーズを満たすために

-

A についてプロのサポートチーム総合的な訓練と運用指針を提供すること

結論: 金属加工 の 先駆 者

工業がより高い精度,速度,効率を求め続けるにつれてCNCタンデムプレスブレーキ製造プロセスを合理化することを目指す製造者にとって信頼性の高いソリューションです 最新の技術,カスタマイズ可能な機能,堅牢な構造により迅速に様々な産業で高精度屈曲のための選択の選択になっている.

統合するデレムのCNC制御システムメタルの形状の未来はここにあります メタルの形状の未来はここにあります メタルの形状はここにあります動いているのはCNCタンデムプレスブレーキ.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!